MEASURING MOISTURE IN TIMBER

How do we measure the Moisture Content (MC) of a piece of Timber?

In a previous Timber Brief we discussed the adverse effects of excess moisture in timber.

BUT: What should be Moisture Content (MC) be?

The regulations state that the MC of a timber frame should be 20% or below prior to lining. During production, Red Stag kiln dry our structural timber to 12-16%. After boron treatment this can increase to a maximum of 18%. The product is then wrapped to prevent rain wetting. If the wrap becomes damaged in transit, it is essential that the wrap is repaired with waterproof tape or stored under cover. Rain wet timber should be immediately stored with fillets between each layer, in a warm dry environment with good air circulation throughout each packet.

Equilibrium Moisture Content:

Over time timber will equalise to the surrounding conditions. This is known as the Equilibrium Moisture Content.

During storage it is important to not store perfectly dry timber next to wet timber or in cold damp conditions. During construction, measures should be put in place to keep frames as dry as possible.

These may include the following:

-

Keep frames off newly poured concrete

-

Raise bottom plates on plastic packers (e.g. Hiandri) to prevent water immersion

-

Cover frames during storage & erection

-

Install roofing ASAP

-

Keep loose timber covered

-

Fillet wet timber well ahead of use

-

Maintain dry airflow throughout the building during construction

These measures will allow builders to demonstrate their professional skills with a straight and true frame that requires little or no rework and early close in.

Timber stacked "in fillet" to facilitate kiln drying, the same principle is applied on site

Packet being wrapped after treatment to protect from weather

The objective, to keep the timber wrapped and dry until it reaches the end user.

Even with the best handling practices described prior, we still need to confirm that out frames are dry prior to the pre-lining inspection.

There are 4 means of measuring moisture in timber:

-

Oven dry method – involves weighing a piece of timber, drying it completely in an oven and weighing it again – scientifically accurate but not practical for a building site.

-

Capacitance meters – non-invasive but may be inaccurate for the same reason as short pronged meters described below.

-

Short pronged resistance meters – measure the moisture near the surface where morning dew or brief surface wetting may affect the reading. Also treatment chemicals are most concentrated near the surface which further falsify the result.

-

Long prong resistance meters – these are more accurate and allow a reading to be taken by hammering the prongs one third of the way through the timber to get an average of the MC in that piece. This type of meter can be a useful addition to the builder’s toolkit. NZS: 1080 provides information on acceptable methods of moisture measurement in timber.

Extended Wetting:

Although highly effective, boron is a mobile, water soluble salt. Wetting over an extended period can reduce its effectiveness. When timber has been exposed to the elements for more than 3 months we recommend a biscuit sample be sent to an approved laboratory for analysis.

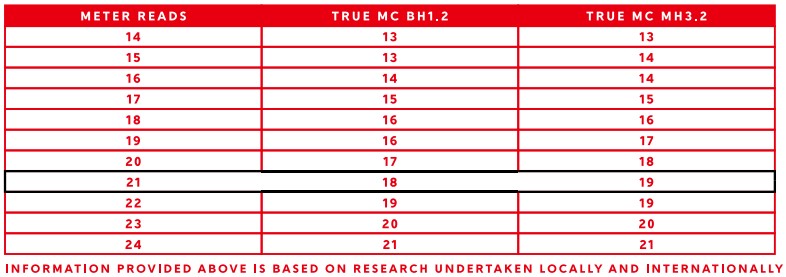

Conversion Tables are available in the Red Stag Timber Managers Handbook to compensate for the effect of treatment chemicals which can affect the meter reading.

Measuring Moisture in a Radiata Pine Using a Meter with Long Insulated Prongs:

Hammer one third of the way through the piece and at least 600mm from the end. Make sure the batteries are fresh, the meter is calibrated correctly and a correction is applied for species and treatment.

For additional technical information about Red Stag Timber Products, ask your merchant to arrange a training programme with their Red Stag Timber Professional.