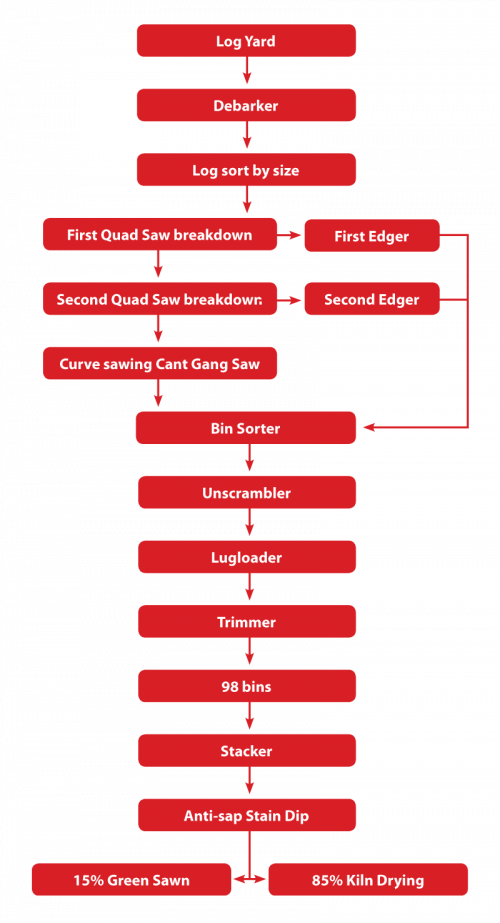

Sawmill Process

Over 8,000 logs per day are cut into a range of sizes, lengths, and grades for markets in New Zealand and around the world.

LOG YARD

The Log Yard accepts deliveries 24 hours a day, five days a week. It has four days of logs on average.

DEBARKER

The Debarker removes the bark from the log. The Bark is used as bio-fuel for boilers to generate electricity and heat the kilns.

LOG SORTER

The Log Sorter, sorts logs into batches allowing maximum production.

NEW SAW MILL

Uses twin quadsaw breakdowns to cut up to eight side boards then saws the cant on a new curve sawing gang for better quality framing. Cuts 10 logs per minute.

BIN SORTER

The Bin Sorter, sorts and trims the boards from both mills by size, grade and length. Operates at 85 pieces per minute, with three operators.

STACKER

The Stacker, stacks and fillets the packets ready for kiln drying. Produces a packet every 90 seconds with five operators.

ANTI-SAP STAIN DIP

Anti-Sap Stain Dip provides protection from sap-stain. There are two anti-sap stain dips, one is domestic strength and provides 6 weeks protection. The other is export strength and provides 3 months protection.